Mesh calcium carbonate is a fine-grained form of calcium carbonate that is characterized by its particle size. The mesh size refers to the number of openings per linear inch in a sieve used to measure the particle size. A higher mesh number indicates smaller particles.

Applications of Mesh Calcium Carbonate

Mesh calcium carbonate has a wide range of applications across various industries, including:

- Paper Industry: Used as a filler and pigment in paper products to improve brightness, opacity, and printability.

- Plastics Industry: Added to plastics as a filler to enhance stiffness, dimensional stability, and heat resistance.

- Paint Industry: Used as a pigment and extender in paints to improve opacity, brightness, and durability.

- Pharmaceutical Industry: Employed as a filler, diluent, and binder in tablets and capsules.

- Food Industry: Used as an anticaking agent, acidity regulator, and calcium supplement.

- Construction Industry: Used as a component in cement, mortar, and plaster.

- Rubber Industry: Added to rubber to improve tensile strength and abrasion resistance.

Properties of Mesh Calcium Carbonate

- Chemical Formula: CaCO3

- Appearance: White powder or crystalline solid

- Particle Size: Varies depending on mesh number

- Density: Approximately 2.71 g/cm³

- Solubility: Insoluble in water

- Thermal Stability: Decomposes at high temperatures to release carbon dioxide.

Types of Mesh Calcium Carbonate

There are different types of mesh calcium carbonate available, each with its own specific properties and applications:

- Precipitated Calcium Carbonate (PCC): Produced through a chemical reaction, PCC has a fine particle size and high purity.

- Ground Calcium Carbonate (GCC):: Obtained by grinding natural limestone, GCC has a coarser particle size and may contain impurities.

- Coated Calcium Carbonate: Treated with surfactants or other substances to improve its dispersion properties and compatibility with other materials.

Choosing the Right Mesh Calcium Carbonate

The choice of mesh calcium carbonate depends on the specific requirements of the application. Factors to consider include:

- Particle Size: The desired particle size will determine the mesh number.

- Purity: The level of purity required will depend on the application.

- Surface Area: The surface area of the particles can affect its properties and performance.

- Cost: The cost of mesh calcium carbonate will vary depending on the type, quality, and quantity.

Production Process

The production process for mesh calcium carbonate typically involves the following steps:

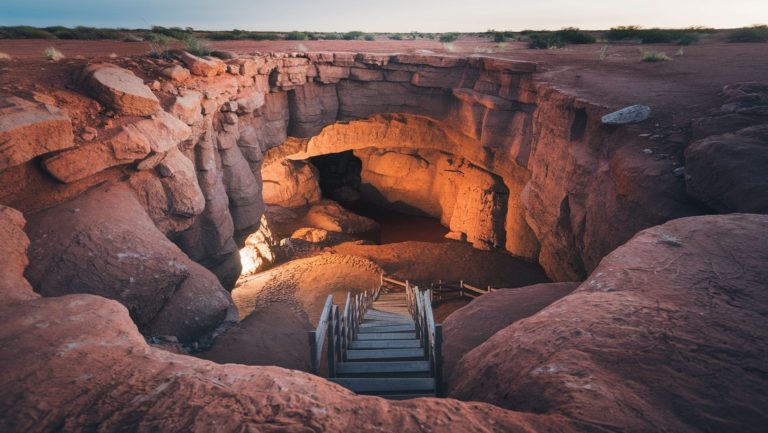

- Mining: Extraction of limestone from natural deposits.

- Grinding: Grinding the limestone into a fine powder.

- Separation: Separation of the desired particle size using sieves or other methods.

- Processing: Additional processing steps may be required, such as coating or chemical treatment.

- Packaging: Packaging the product into appropriate containers for storage and transportation.

By understanding the properties, applications, and production process of mesh calcium carbonate, you can select the most suitable product for your specific needs.

read more : Price Per Kilogram of Calcium Carbonate: A Comprehensive Guide